* This article was serialized irregularly by Yoshihiko Murayama, a former advisor of our company.

At 1980:8 am on August 16, 9, a gas explosion occurred in the Golden Underground Shopping Center in front of JR Shizuoka Station.Then, five minutes later, a larger secondary explosion was triggered, causing an unprecedented catastrophe of 46 casualties.In the evening edition of the Mainichi Shimbun on the day of the event, the misery of the gas explosion accident was reported under the big headline "The person who blows away the heavenly pillar of fire, just like the battlefield."Investigations after the accident did not identify the cause of the explosion, but it was certain that the damage was exacerbated by the fact that there was no device in the underground mall to detect gas leaks and issue alarms.The Ministry of International Trade and Industry, which emphasized this, obliged to install gas leak alarms in specific underground malls and basements in February of the following year.In this way, the horror of gas accidents has resulted in a great appeal to the world about the need for gas leak alarms.

Gas leak alarms for household use and semiconductor LP gas have already begun to be sold in August 1969, and in 8, the High Pressure Gas Safety Association began to certify alarms.

The sensing principle of a semiconductor LP gas leak alarm utilizes a physical phenomenon in which the electrical resistance of a semiconductor changes when LP gas molecules are adsorbed on the surface of an n-type semiconductor.Therefore, even if other gas molecules (for example, alcohol) other than LP gas are adsorbed, the same phenomenon occurs, which has a drawback of giving a false alarm, which hinders its widespread use.

In response to these social needs, Nemoto conducted research to develop a new type of sensor that would improve the shortcomings of commercially available gas leak alarm sensors.As a result, I was convinced that the contact combustion type sensor had good linearity with the gas concentration, could easily distinguish it from miscellaneous gas, and could obtain an accurate alarm, and started developing this type of sensor in August 1978. ..After repeated experiments, we devised the material of the gas sensing element and the contact combustion catalyst, and developed a new sensor with good performance.It was announced in May 8 for city gas and in May 1979 for LP gas.

Although the new sensor has excellent initial performance, it has not yet been adopted by domestic alarm manufacturers, although it has shown interest because it does not yet have sufficient background data to guarantee it for three years.Therefore, in order to obtain UL certification in the United States and prove the quality, we made an alarm with a new sensor and applied for a UL certification test.Then, in February 3, he passed UL and started selling to the American market.The gas explosion accident in August 1980 mentioned at the beginning was a tailwind for gas leak alarm manufacturers, and the production of alarms began to increase, but the timing was good, and the performance of Nemoto's new sensor was bought. It was adopted and started mass production.

|

|

|

↑ Nemoto alarm at that time

|

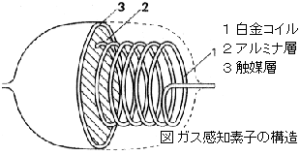

Nemoto's contact combustion type gas sensor uses a gas detection element having a structure as shown in the figure, and burns flammable gas in contact with the surface of the element with a catalyst, and the combustion heat raises the temperature of the platinum coil.The features of Nemoto's contact combustion type gas sensor whose electrical resistance changes linearly with temperature are as follows.

- The output linearity is excellent in the gas concentration range from 0 to LEL (Lower Explosive Limit).

- The gas response speed is very fast.

- The influence of ambient temperature and humidity is extremely small.

- Maintain stable properties over the long term.

- Has good reproducibility.

- The lower limit of measurable gas concentration varies depending on the gas type, but is about 50 ppm.

|

| ↑ Comparison of old and new sensors |

It has been 20 years since the development of Nemoto's contact combustion type gas sensor, but now it has been widely used in various measuring instruments such as gas leak alarms not only in Japan but also overseas, and it is particularly stable in quality. It has received a very high evaluation for its reliability.And so far, development has been done to apply it to various uses, and now

As shown in the table, the number of types has increased, and the cumulative number of units sold so far has exceeded 1400 million.We hope that we will continue to develop new sensors that take advantage of the characteristics of the contact combustion type, respond to various needs, and contribute to society in the field of safety and disaster prevention.

table.List of Nemoto contact combustion type gas sensors

| Test gas type | Model | 特性 | Main uses |

|---|---|---|---|

| ・ General flammable gas methane gas propane gas butane gas Hydrogen gas alcohol |

NAP-2A | High-performance, general-purpose type | City gas alarm Densitometer |

| NAP-55A | Small size and low power consumption | ||

| NAP-50A | Small size, low power consumption, low alcohol sensitivity | ||

| NAP-3A | High-performance, general-purpose type | LP gas alarm Densitometer |

|

| NAP-66A | Small size and low power consumption | ||

| NAP-100AD | High speed response and high durability | Industrial alarm | |

| NAP-100AH | High-speed response, high selectivity, high durability | Fuel cell alarm | |

| ・ Incomplete combustion waste gas CO Hydrogen gas |

NAP-70A | High sensitivity, high speed response, low alcohol sensitivity, low power consumption | CO alarm |

| NAP-78A | High-speed response, high accuracy, and high durability | Water heater | |

| NAP-78R | High-speed response, high accuracy, and high durability |

← Reference material:

Changes in the installation rate of LP gas alarms and the number of accidents

(From the materials of the Gas Alarm Industry Association)